2020-08-05

The design of gating system is closely related to the service life of the mould. First of all, according to the type of mould material used, structural characteristics, technical requirements and average wall thickness, the process parameters of die casting production were determined. Then, according to the weight of the product, calculate the area of the feed port. Next, we can design the gating system.

The determination of process parameters is very important. If the area of the feed port is determined by feeling alone, it is likely that the product can be filled only at a very high speed. For the material with poor fluidity, if the gate area is not changed, the product defects can only be solved by adjusting the process parameters.

1. Temperature and gating system

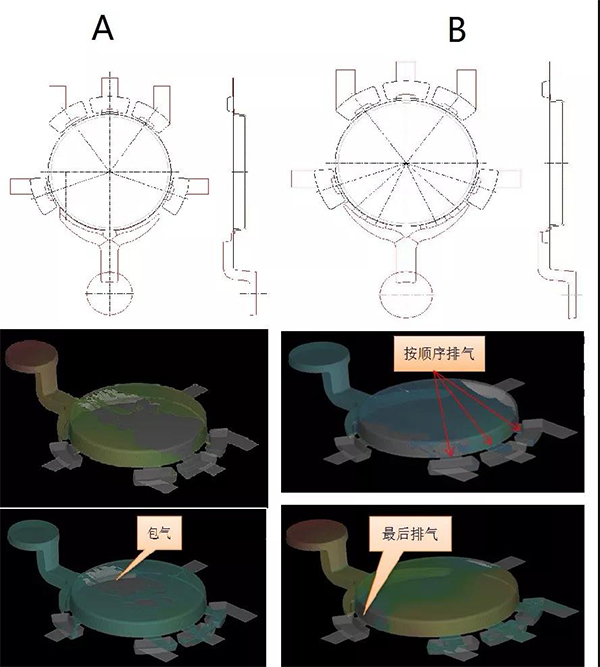

Temperature is one of the decisive factors of process parameters. As shown in Figure A and B above, the width and thickness of the feed port are exactly the same. But the effect of filling is completely different. The filling of figure A is from the outside to the inside, resulting in increased flow rate and increased heat generated. Because the surface temperature of mould increases greatly, the thermal strength performance decreases.

This is not the case with the filling of figure B. Because the temperature rise of material in Figure B will be lower than that in figure A, the working environment is good, the probability of erosion will be less, and the mould life will be longer.

2. Heating and cooling of mould

Heating of mould

At present, there are three main methods of mould preheating. Filling heating, gas heating, oil temperature heating. Although the three kinds of methods can achieve the purpose of temperature rise, the effects on the materials are very different.

Filling heating is through slow and low pressure filling, the heat of material liquid is directly transferred to the mould surface. The temperature of die casting aluminum alloy liquid is 630 ℃ - 650 ℃. When the mould surface receives the heat from room temperature, it will lead to large stress caused by surface thermal expansion and internal temperature difference.

Gas heating is by burning gas. Although the heat is also transferred from outside to inside, there is a gradual heating process, and the stress generated will not be so large.

Oil temperature heating is through the high temperature oil into the heating. It takes a long time for heat to pass from the inside to the outside, so the stress generated will be very small.

Cooling of mould

The cooling water or oil path takes away the heat through the water or oil running inside the mould, so that the surface cooling is gradually completed. As long as the cooling channel is not too close to the sharp, corner or shape position, there will be no big problem.

The main function of coating cooling is to make the mould surface have a layer of protective film to prevent mucous membrane. A lot of spraying immediately after filling is a big mistake, because that is to quench the material. Some of them are specially used to spray a few more times on the splitter cone and flow channel. Because they think the temperature here is the highest, they have to spray more to make sure the temperature can drop down. In fact, as the splitter cone and flow channel are located at the bottom of the mould, the coating liquid on the top must flow through the bottom. Therefore, such "key care" may be lower than your expected value.

To improve the design of the structure and gating system and adopt the most favorable heating or cooling method is to prevent the premature failure of the mould. Otherwise, even the best quality steel will seriously shorten the service life of the mould because it exceeds the limit of its toughness and strength.

電話:0757-2332 2638

傳真:0757-2332 2619

郵件:fzz@strongmetal.com.cn

地址:佛山市順德區(qū)陳村鎮(zhèn)石洲工業(yè)區(qū)30號

備案號:粵ICP備09051653號